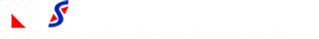

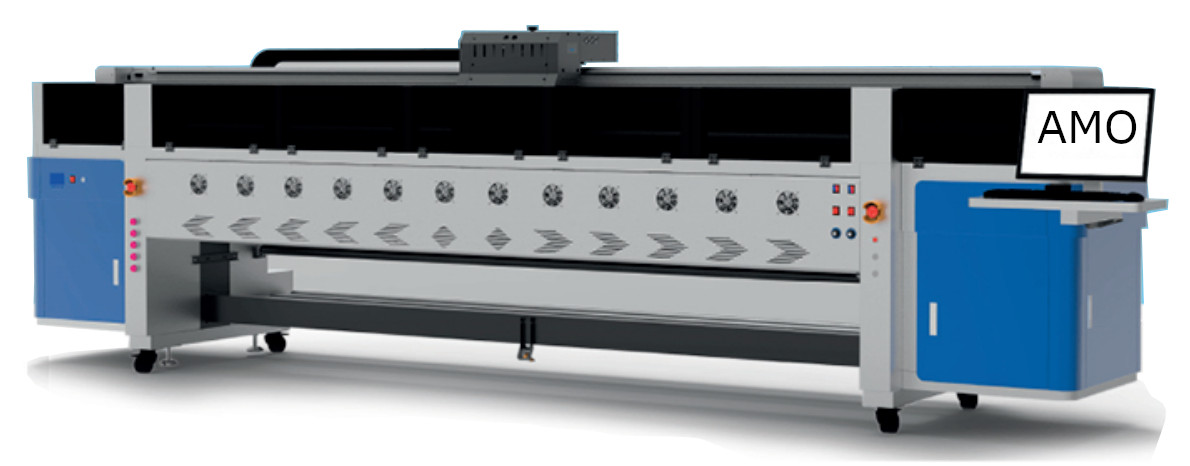

AMO UV Inkjet Printer AM3200UV4k24i-EL for 3.2meters Soft and Elastic Film with 4 Konica 1024i Printheads

Amo Soft and Elastic Film UV Inkjet Printer AM3200UV4k24i-EL with 4 Konica KM1024i printhead

This UV Inkjet Printers series with EL suffix in model name are equipped with Special rolling system especially for very soft and elastic material like soft film. If you just need to print on normal Flex banner,coated flex banner,vinyl,mes,one way vision,canvas, then no need to buy this inkjet printer,please see those models with ES suffix in model name.

1.Printhead Nozzle Heating System& Ink Circulation: The Printhead nozzle plate integrates a heating function to ensure optimal ink flow stability across varying temperature environments. The built-in ink

circulation system prevents pigment sedimentation within nozzles, effectively reducing nozzle clogging risks.

2.Fully Transparent Secondary Ink Tank Design &Independent Color Pressure Control:(1) Transparent construction enables easier troubleshooting and reduces maintenance time.(2)

Independent pressure adjustment mechanisms optimize ink consumption efficiency.

3. Single Motorized Pressure Roller System & Silent Guide Rails/Sliders: (1) Allows real-time adjustment of individual pressure rollers during printing operations to eliminate material wrinkling without interrupting production, minimizing material waste. (2) High-speed silent guide rails ensure smoother printhead movement, enhancing printing precision while reducing operational noise. This design minimizes mechanical wear and extends guide rail lifespan.

4.Adjustable Vacuum Platform & Roller Speed Modulation:(1) Enables manual airflow adjustment during printing to resolve material feeding issues caused by excessive vacuum, ensuring smooth feeding of materials with varying thicknesses. (2) The roller power regulation system enhances compatibility with diverse material types for both feeding and collection operations.

5.High-Power Heating/Drying System: Features segmented heating zones to improve material ink absorption and color fastness. Incorporates a proprietary built-in thermal air

circulation chamber coupled with a cold air diversion system, enabling rapid post-drying cooling to ensure finer details and glossier finishes.

Machine Parameters

Maximum Print Width 3200MM

Printheads: 4 Konica1024i

Printing speed:

Extemal light Mode 45m²/h

Internal Light Mode 22m²/h

Media:any soft and elastic materials:ceiling soft film, and normal material like Flex banner,vinyl,one way vision,mesh,wallpaper/colth,polyester Cloth,backlit film,Photo paper, Canva etc

RIP Software: color management software

Power: AC220±10.50HZ60HZP4500W

Printer PackingSize: L5300*W1180*H1700/L5600*W1250*H2100

Net /Gloss Weight: 2500kg/2800kg

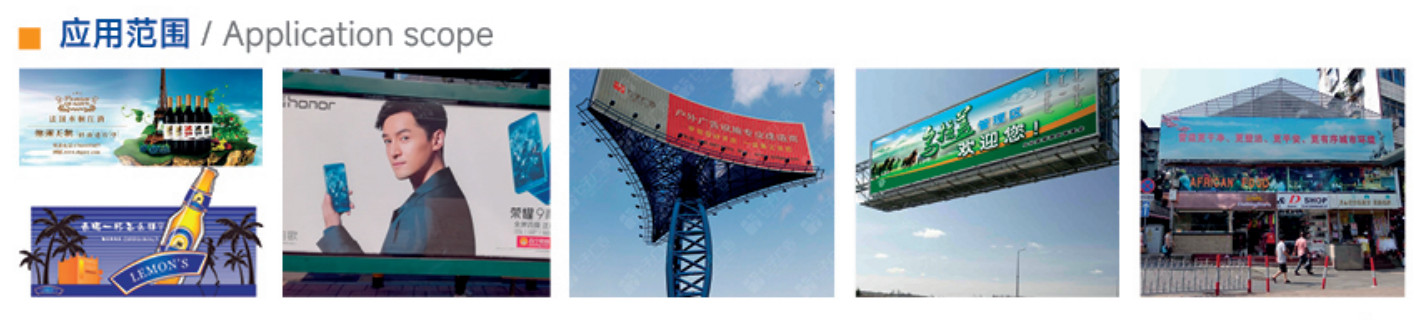

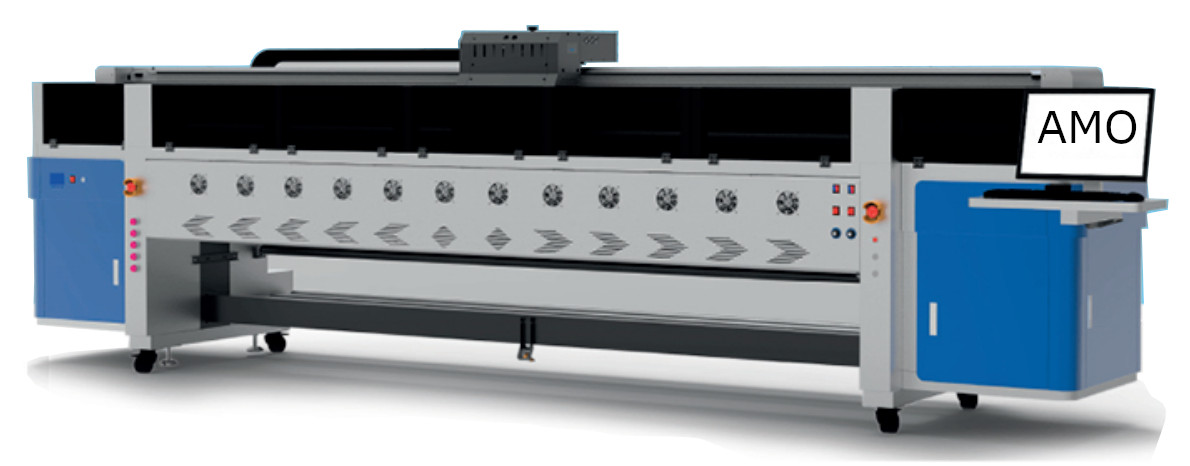

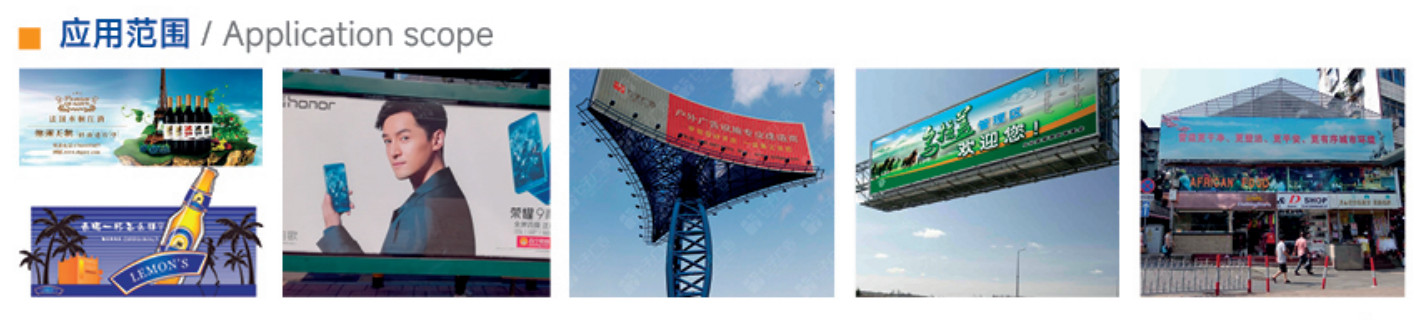

Applications: